PVD Coating Equipment - Hard Coatings

STAR series PVD coating systems are designed for tool manufacturers of all sizes looking to transition from PVD outsourcing to In-House PVD. We offer 10+ most trendy coating types in the marketing including diamond-like carbon (DLC) with fast cycle time, easy operation, and a great cost-performance ratio.

STAR-E100 PVD Coating System

Compact PVD Coating System for Small Batch operations.

- Loading Volume: 200 L

- Coating Diameter: 350mm / 13.78”

- Coating Height: 250mm/9.84”

- Arc Sources: 6 Sets

- Cycle Time: 3 hours

- Footprint: L1662 x W 1585 x H 1810mm

Tools Per Batch

180+

Based on ø 1/4” x 3” OAL

Coating Types

10+

Runs Per Day

6

STAR-E700 PVD Coating System

High-capacity PVD Coating System for Large-Scale Operations

- Loading Volume: 600 L

- Coating Diameter: 580mm / 22.83”

- Coating Height: 750mm/29.52”

- Arc Sources: 6 Sets

- Cycle Time: 4 hours

- Footprint: L2500 x W1850 x 2200mm

Tools Per Batch

2000+

Based on ø 1/4” x 3” OAL

Coating Types

10+

Runs Per Day

4

STAR-S800 PVD Coating System

High-capacity PVD Coating System for Large Molds

- Coating Diameter: 500mm / 19.7”

- Coating Height: 600mm/23.6”

- Arc Sources: 4 Sets (Rectangular)

- Cycle Time: 5 hours

- Footprint: L3226 x W2502 x H2113 mm

Tools Per Batch

1920+

Based on ø 1/4” x 3” OAL

Coating Types

10+

Runs Per Day

4

PVD Coating Equipment - For Functional Coatings

Searching the perfect PVD coating solution for your unique products or specialized applications could be a daunting task, consuming both your time and energy. Aurora is here to guide you through this journey. Whether you seek decorative coatings, optical coatings, conductive coatings, or plastic metalizing solutions, we have the answer. Our systems are fully customizable and can be tailored to meet your exact specifications.

Decorative Coating System

The Most Reliable Decorative Coating System

- Coating Diameter: 1,200mm / 47.24”

- Coating Height: 1,450mm/57.09”

- Technology: Cathodic Arc

- Cycle Time: 15-40 minutes

- Footprint: L 3927 x W 4213 x H 2504mm

Plastic Metalizing Coating System

Flexible and economical, the LEAN 710 Metalizing System is designed for multiple metalization applications.

- Load Diameter: 710mm / 28.0”

- Load Height: 1220mm/48.0”

- Technology: Thermal Evaporation/Sputtering

- Cycle Time: 4 minutes

- Footprint: L 3810 x W 2032 x H 2438mm

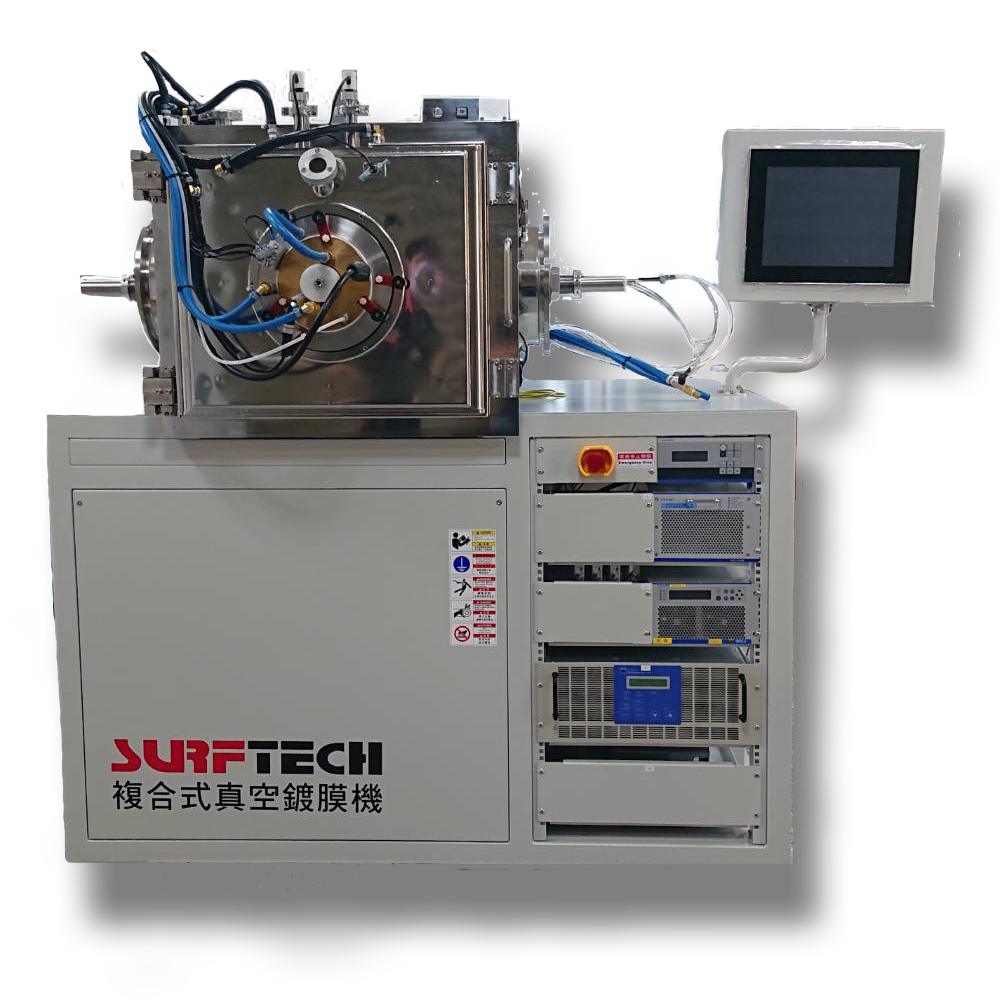

Fuel Cell & Battery Coating

Perfect for conductive coatings, custom chamber configuration for any products.

- Load Diameter: 300mm / 11.81"

- Load Height: 400mm / 15.75”

- Technology: Cathodic Arc/Sputtering/E-Beam