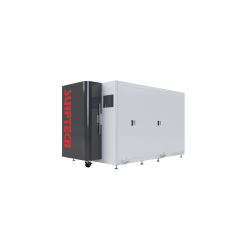

STAR-E700 PVD Coating System

STAR-E700 is the brand new PVD coating system developed by SURFTECH Group, integrating the knowledge of providing PVD service in the industry for 30 years. By streamlining the supply chains and partners, STAR-E700 incorporate the most innovative technology and reliable components to deliver the best coating quality and most reliable machinery the money can buy. Other than the typical ceramic hard coatings available on this machine, it allows to deposit the trending diamond-like carbon (DLC) coating in the same chamber. If you are looking for the most versatile for large production and the fastest return on your investment, STAR-E700 is the best choice.

Variety of thin film structures

The STAR-E700 PVD coating system is configured to be capable of producing single-layer, multi-layer, nano-composite and nano-gradient hard coatings.

Heavy-duty vacuum system and flexible chamber working temperature

The equipment uses turbo molecular pumps to achieve vacuum pressures down to 3 x 10^-6 Torr and operates at temperatures from 180°C to 450°C (356°F to 842°F), suitable for processing tool steels, HSS, titanium alloy, and tungsten carbide. It can also handle materials like aluminum, brass, and plastic at lower temperatures.

Cathode design for high uptime

6” circular cathode evaporator is easy to install and remove. Quick release of water, power and gas connections allows one operator to complete cathode switch within 15 minutes. Each cathode material runs on average of 50 - 100 cycles.

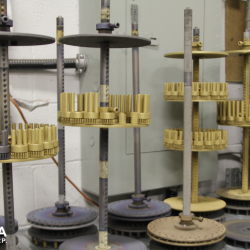

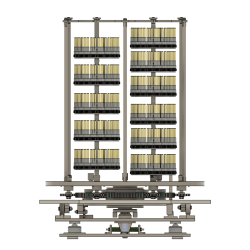

6-axis planetary carousel

Planetary design of the carousel maximizes the loading capacity of any tools and parts. It can load up to

2,448 pieces of 1/4” OD x 3” OAL (6 mm OD x 80 mm OAL) round tools

900 pieces of 1/2” OD x 3” OAL (12 mm OD x 80 mm OAL) round tools

612 pieces of 5/8” OD x 3” OAL (16 mm OD x 80 mm OAL) round tools

3,000+ pieces of inserts

Friendly user interface

15” touch screen allows operator to monitor the process easily with its graphical platform. All standard coating types can be processed in fully automatic mode or manual mode if required.

Process log and remote diagnosis

The equipment software allows process monitoring and keeps every process log, so it allows engineers to diagnose on-line and help trouble-shooting together in the shortest time manner when needed.

Vacuum Chamber

- Construction: 304 stainless steel with chamber shutter

- Cooling: Double walled chamber with water cooling

- Chamber Size: Φ 920 × 960 mm (Φ 36.2” x 37.8”)

- Effective Plasma Zone: Φ 720 × 650 mm (Φ 28.3” x 25.6”)

Vacuum Arc Evaporation Source

- Cathode: 6 sets of Φ150 mm circular vacuum arc evaporator/ Auto arc triggering

- Power Supply: 6 sets of 250A pulse DC power supply

- Water Cooling: 1 spare set of cathode cooling base

Pump System

- Primary Mechanical Pump: 120 m3/h (ULVAC LS120A-L or comparable)

- Root Pump: 500 m3/h (ULVAC NB600B or comparable)

- Turbomolecular Pump: 2200 l/s (Osaka Vacuum TGkine2204MBWB-B or comparable)

- Vacuum gate valve: ISO250 Vacuum valve

- Dust Filter: Filter for vacuum route

Vacuum Measure & Component

- Hot filament ionization gauge: 1 set

- Pirani Gauge: 2 set

- Capacitance gauge: 1 set (INFICON025D)

Tools Per Batch

Coating Types

Runs Per Day

Gas Flow Control

- Mass flow controller: Argon 1 set Horiba or comparable

- Mass flow controller: Nitrogen 1 set Horiba or comparable

- Mass flow controller: Acetylene 1 set Horiba or comparable

Heater

- Heater Specification: 30kW 6 sets (chamber sides and door 2 each)

- Controller: 1 set of PID temperature control / 2 sets of thermocouple

Software Function

- Manual and automatic process control

- Coating log and record & Self-monitoring / protection

- 2KW uninterruptible power supply (UPS)

- ASAIR water flow sensor

- Remote diagnostics / Safety interlock protect function

Cycle Time (2 µm)

- Batch Cycle Time: 3-4 Hours

Equipment Footprint

- Footprint: L 3750 x W 2100 x H 2250 mm (L 147.7” x W 82.7” x H 88.6”)

- Recommended Operating Footprint: L 5000 × W 5000 mm (16’ x 16’)

Loading Carousel

- Carousel: 2 sets of carousel & loading wagon

- Carousel Configuration: 5-axis planetary carousel

- Loading Capacity – Weight: 800 kg

- Plates – 17 slots (with 4-in-1 holder): ø 1/8" - ø 1/4" (or ø 3 - ø 6 mm)

- Plates – 25 slots: ø 5/16" - ø 1/2" (or ø 8 - ø 12 mm)

- Plates – 17 slots: ø 3/4" - ø 1" (or ø 20 - ø 25 mm)

Carousel Loading Capacity

- Small Round Cutting Tool: ø 1/4” x 3” OAL - 2,448 pcs

- Regular Round Cutting Tool: ø 1/2” x 3” OAL - 750 pcs

- Large Round Cutting Tool: Up to ø 3/4” x 4” OAL - 408 pcs