JMAP-500BM Manual Air Lapping System

The JMAP-500BM Air Lapping Machine, manufactured by SMKS, is a specialized device designed for edge prepping, deburring and polishing of tools. This equipment is particularly adept at solving complex polishing and deburring challenges, providing high-quality mirror finishes.

Increase Tool Life and Performance

Air lapping process, that can bring the surface roughness down to 0.1 µm, has been widely used on cutting tools by the job coating centers or tool manufacturers. It has been proven that polished PVD coated tools increases minimum 25% to 50% more life compared to unpolished PVD coated tools.

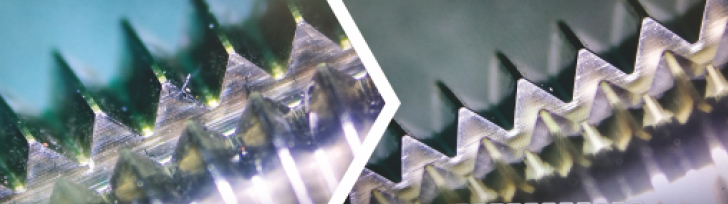

Edge-Prep & Deburring

The JMAP-500BM excels in applying edge-prep and deburring on cutting tools, significantly enhancing tool performance and longevity. It is capable of creating 3 to 12 µm radius on the sharp edges, ensuring a smooth and uniform edge, and reducing wear of the tools and the risk of chipping during operations.

No Blind Spot

JMAP-500BM air lapping system comes with SM-25 polishing media for cutting tools. The media is very fine so it can reach irregular surfaces easily. It can polish the hard-to-reach grooves on either 2-flute or 6-flute tool without any problem.

Machine Dimensions

- Dimensions: D 530 x W 800 x H 1,700 mm |20.86" x 31.5" x 66.93"

- Weight: 120 kg | 265 lb.

Work Piece

- Maximum workpiece size: 200 x 200 x 50mm | 7.87" x 7.87" x 1.96"

Power Requirements

- Voltage: 380V, 3 Phase 4 Wire, 50 Hz

- Wattage: 0.5 kw

Air Requirements

- Air Pressure: ≥0.6 Mpa/cm³

- Connector: 12 mm

Edge Prepping

Improves edge strength, enhances chip removal, prevents material from sticking to the surface

Polishing

Achieve smooth and mirror finish through air lapping polishing

Deburring

Removes micro burrs from edges, improves finish, enhances durability and wear resistance, strengthens the edge