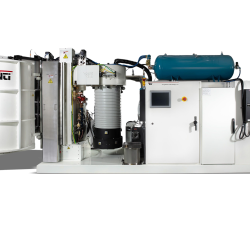

LEAN 710 PVD Metalizing System

Introducing the LEAN 710 – a groundbreaking innovation in thin-film deposition technology for PVD metalizing. Its field-convertibility sets the LEAN 710 apart, allowing seamless transitions between thermal evaporation and magnetron sputtering, or vice versa. With the LEAN 710, you unlock the power of multiple technologies within a single platform, providing unmatched flexibility and versatility.

Applications:

- Automotive lighting & trim

- LED lighting

- Chrome finishing

- Decorative packaging

- Solar energy

- Plastic hardware

- Appliance handles & knobs

Features:

- Rapid cycle in 4 minutes

- Multiple matched pumping package options

- Large plenum cryotrap, options for cryochiller

- Up to 60kW per cathode for sputtering

- PLC-controlled process, open-architecture with password protection for customer-controlled program modifications

- Data-logging

- Fixturing and process development support

- Ethernet-ready for remote support

Vacuum Chamber

- Chamber Size: Φ 825 × 1575 mm (Φ 32.5” x 62.0”)

- Effective Plasma Zone: Φ 710 × 1220 mm (Φ 28.0” x 48.0”)

Evaporation Source

- Thermal Evaporation

- Single or dual cathode sputtering process available

Pump System

- Mechanical Pumping Package (Leybold, or equivalent)

- Root Pump: 15 hp motor (Leybold, or equivalent)

- Diffusion Pump: Leybold, or equivalent

Vacuum Measure & Component

- MKS capacitance manometer: 1 set

- INFICON wide-range cold cathode/Pirani Gauge: 1 set

- INFICON Pirani Gauge: 2 sets

Coating Cycle

-

A complete cycle may include the following operations in less than 4 minutes:

- Pumping

- Pre-treat glow

- Base coat HMDSO

- Metal deposition

- Top coat HMDSO

- Post-treat etching

- Venting