Unveiling the Benefits of Corrosion-Resistant PVD Coatings

June 11, 2024

Air Lapping is the Future of Precision Finishing!

November 8, 2024Elevate Your cutting Tools with Air Lapping System: All-in-One Edge-Prep, Polishing and Deburring

What is Air Lapping?

Lapping is a polishing process to remove a small amount of material from the surface, typically no more than a few microns. In air lapping, the abrasive media was carried by compressed air and sprayed from a nozzle to the work pieces for grinding and polishing. Air lapping is a simple, robust and affordable treatment which have been widely used in improving surface finishing on cutting tools.

1. Polishing

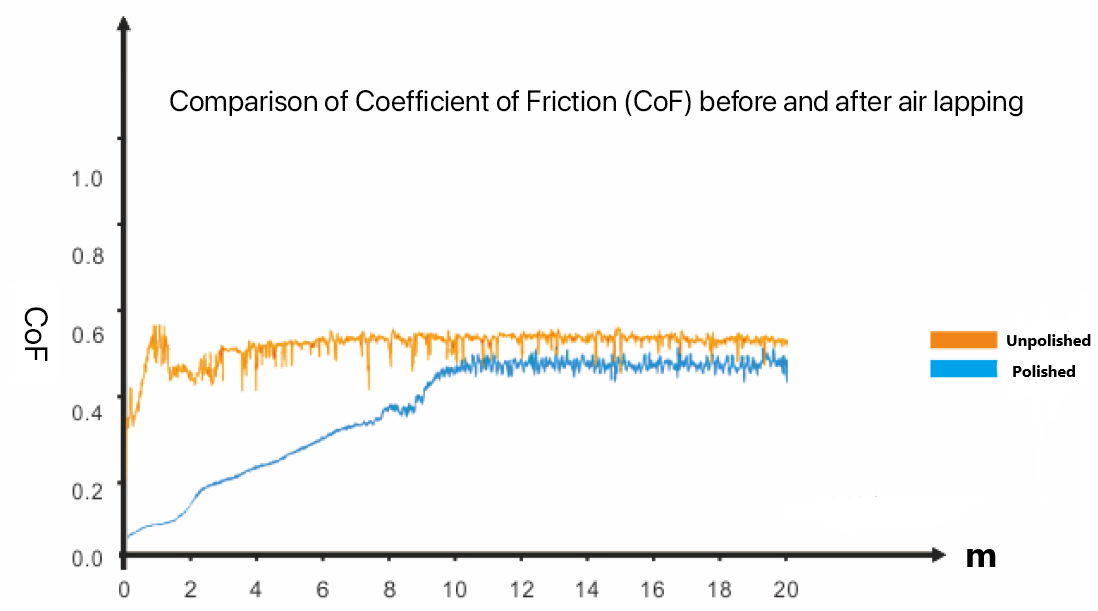

The selected polishing media can reduce surface roughness Ra for 0.1 µm or less. The polishing media can only remove very little PVD coating material (around 100 nm). The friction of the coated cutting tools after air-lapping reduces dramatically, resulting in less wear damage and longer service time in machining. As a result, the polished surface is smoothened out to bring the most shininess you can get on tools.

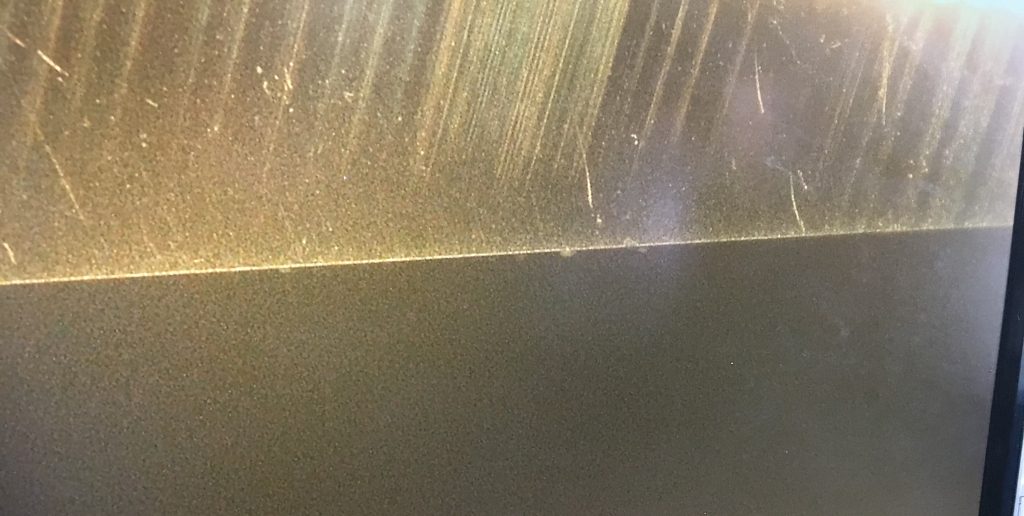

2. Edge Preparation

The sharp edge on the tool is slightly rounded to give it strength and prevent chipping. Air lapping can be used to round the edge of cutting tools to improve the edge strength. This process is called edge preparation. Edge preparation will also enhance the cutting chip removal in machining and prevent materials buildup on the sharp edge.

BEFORE

AFTER

3. Deburring

Air lapping is also used to remove the sharp burrs and imperfections on the cutting tools. This deburring process would dramatically reduce the friction, improves finish and life span of the cutting tools.

BEFORE

AFTER

In Summary:

Air lapping would dramatically improve the lifetime of the cutting tools through polishing, edge preparation and deburring. Studies demonstrated a minimum 25% to 50% life increase of PVD coated tools compared to untreated tools.

Contact Us