How to choose between TiN, TiCN, AlTiN or TiAlSiN for cutting tools?

June 2, 2021

Beauty Is Only Skin Deep: Surface Modification

July 7, 2021Ever-evolving PVD coating materials and technologies

We are more or less familiar with the TiN coating by PVD process for tool life improvement. Variations such as TiCN, TiAlN, AlTiN, TiCrN, etc., are, in fact, all descending from the good old TiN. The extra element added to TiN serves unique purpose of either enhanced thermal stability or better hardness and wear resistance.To further tune in desirable mechanical and tribological properties, more transition metal nitrides of ZrN, CrN, ZrN/CrN, AlCrN, AlTiCrN, and the exotic DLC, ta-C, and diamond films are developed for various industrial applications. With the advent of plasma technology, the possible recipe of new coating materials with multiple elements is beyond imagination.

Furthermore, enhanced and combined physical and chemical properties of thin film coatings can be achieved through coating structure design. Therefore, when choosing the best coating for your jobs, the options are wide-open, and possibly you can opt for a custom-designed coating of your own.

What is ZrN Coating?

ZrN coating was commercialized in 80s as an alternative to TiN with compatible tribological properties with greater corrosion and chemical stability for non-ferrous metal machining. Its unique brass-like color makes ZrN a popular decorative coating for kitchen and bathroom accessories.What is CrN Coating?

CrN coatings for molds, dies, and punches were commercialized around the same time of TiCN coatings. Despite its lower hardness than TiN, the unique properties of corrosion resistance, chemical stability, and low friction coefficient make CrN the perfect replacement for hard chrome plating, especially when the cost variation between plating and PVD is justified by the growing waste disposal charge. A good example is the IC packaging dies, which have migrated from using the standard electroplating of hard chrome for wear resistance to applying PVD coated CrN thin film for its superior hardness and ease of mold release.

What is ZrCN/CrCN Coating?

Both ZrN and CrN can be further extended to ZrCN and CrCN by adding carbon atoms to their crystalline matrix to enhance their tribological properties. The modern woodworking industry embraces these two coatings for the high-speed, low thermal conductivity planing and shaping of wood and wood-derivative materials.These carbonitride coatings are usually applied to woodworking tools with a multi-layered configuration for additional strength and thermal stability.

What is AlCrN Coating?

When adding Al to CrN, AlCrN becomes a very unique coating with superior hot hardness, oxidation resistance, and wear resistance for high-speed, continuous metal cutting. At higher working temperatures, both Al tends to stabilize the oxidation process by forming a thin passivation oxide layer between the coating and the workpiece.By doping Y or Nb, the oxidation and plastic deformation kinetic can be further restrained through a grain-refining and grain boundary locking mechanism.

What is AlTiCrN Coating?

One more exotic coating is the AlTiCrN, which was upgraded from AlTiN by adding Cr to enhance its inter-layer adhesion for the most demanding metal cutting jobs. As PVD coatings are getting super-hard at higher temperatures, the design criterium is more important in balancing the residual stress between the cohesive strength of coating materials and the adhesive strength at the coating interfaces.

What is Diamond/DLC/ta-C Coating?

For innovative coating materials, we should not leave out the diamond, DLC, and ta-C family as described in previous articles. These super hard and low friction carbon films come with two weakness of high brittleness and low thermal stability. Again, the PVD coating technology has find a few ways to cope with these weaknesses through doping and coating architecture, as will be narrated later.The possibility of creating new coating materials by mixing in variety of elements such as C, V, B, Y, Nb, or even O is growing with the advent of the plasma technology and power source development. Engineers’ choice for tool protection is no longer limited to nitrides. With the fine control of the coating microstructure and its physical, chemical, optical, or biomedical properties, the horizon of applying sophisticated functional coatings to non-contact applications is ever-widening. In addition to new coating materials, the list is endless when we advanced from the very simple binary TiN coating to the most exotic, multi-element, and multi-layered designer coating for the most challenging machining and non-machining jobs.

Coating enhancement through design

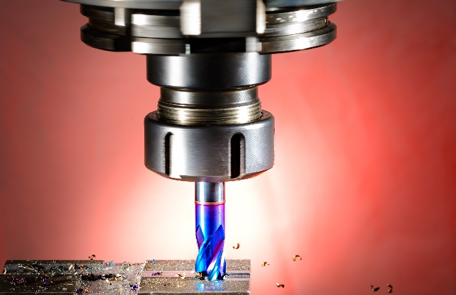

As the work material evolves from iron, carbon-steel, alloy steel, Al-alloy, Ti-alloy, to super-alloy, and composite materials, the development of coating technologies follows closely, both in coating materials and coating architectures. To cope with the ever-increasing challenge in cutting and forming processes, all coatings need to manage its residual stress and thermal load before reaching their predicted life cycle. Here in coating industry, we rely on a well-designed coating architecture to further mitigate the challenge.

- Multi-layered coating configuration: two compatible coating materials such as TiN/TiCN or CrN/CrCN were deposited alternatively with each other, and form a nano-scaled and multi-layered film structure.

This architecture induces additional compressive residual stress between each bi-layer for additional hardening. And, most importantly, the abundant boundaries between each two-layer block or arrest the micro-crack propagation effectively.

When crack propagation slows down, so is the plastic deformation, and the outcome is the apparent increase of the coating hardness. - Functionally modified coating: We can combine advantages of a set of coatings to compensate their weakness if used individually. Most coatings are not superior all around. They all come with their individual weakness. Therefore, we can design a coating architecture the way that a set of coatings work together as a super coating.

For example, in high-speed machining of low thermal conductivity materials, the heat dissipation through cutting chips is insufficient. The usual choice of the high-temperature-resistant AlCrN coating won’t be able to protect the tool material from over-heating and softening. The reason is the low thermal conductivity of AlCrN itself. So, one solution is to interlace AlCrN with TiSiN, an equally strong coating with a great thermal conductivity.

The combination provides both a hot hardness and a proper heat dissipation to the machining process, and problem solved. - Nano-composite (nc) architecture: Hardness is never the only goal of protective coatings. There are additional concerns of adhesion, oxidation, friction, etc. With the advent of the composite material technology, coating architecture evolves toward the same direction as well.

In short, the PVD nc-coating such as TiSiN possesses an innovative composite configuration with super-hard TiN particles residing within a tough and amorphous Si3N4 matrix. This nc-coating provides the best of hardness and toughness at high temperature through a self-assembled composite structure. - Compound coating architecture: An effective coating should be well-adhered to the substrate, well-balanced in thermal expansion and residual stress distribution throughout the coating depth, and functionally tailored to the contact surface requirement. Therefore, when designing a proper coating architecture, we need to ensure that the substrate interface, the body, and the top surface of the coating act like one integrated unit. So, a good compound coating should start with an adherent interface layer, which bridges between the tool substrate and the coating body physically and chemically.

The coating body provides the main functionality for the tool. The integrity of the coating body should be maintained and transit from layer to layer, or by means of a gradian transition from substrate to surface. And, finally, a top layer with ultra-low friction for wear resistance, or is chemically inert for non-stick cutting, forming or sliding.

Vanish line between PVD and CVD

There used to be a definitive boundary between PVD and CVD technologies.Each technology severs its unique market. If your workpieces need a thick and diffusion-level bonding at higher temperatures, look for immersion type of coverage, or possess large aspect-ratio features, you should stick with CVD. But, if your workpieces are heat sensitive, requiring tight conformality and tolerance of coatings, or if you need flexibility in coating constituents and microstructures, you should choose PVD technology.

However, with the advent of plasma technology and power source development, the line between PVD and CVD is vanishing. PVD is taking a big leap over the CVD territories now. Metal Plasma Ion Implantation Deposition (MPIID) pioneered by I. Brown et al takes advantage of a high-power pulsing-bias to lay down an ion-mixing bond layer before switching to a conventional cathodic arc PVD process.

Dr. Teers and Dr. Wang patented on sputtering and arc-PVD respectively the plasma conversion mechanism, which triggered a CVD reaction with an energetic metal plasma flux, in-situ within the PVD process. And, the latest development in HiPIMS, mid-frequency pulsing magnetron drive, and bi-polar/asymmetric pulsed biasing grants PVD superior advantage over the conventional PVD and CVD technologies. We are moving into a new era of tailor-designed PVD coatings for demanding industrial functionalities.

Aurora Scientific Corp. is a research-centric professional coating service and PVD turn-key system provider. We are backed with a 30-year job shop service experience in Asia and North America. In addition to our cathodic-arc PVD production units, we are also equipped with UBMS, PECVD, and HiPIMS capacities. We are willing to work with you solving any of your needs for protective or functional coatings.